-

من آلة صنع الرمل V

رسالة على الانترنت

المزيد من المعلومات

-

الغربال

رسالة على الانترنت

المزيد من المعلومات

-

مغذي الهزاز

رسالة على الانترنت

المزيد من المعلومات

-

سيور متنقلة

رسالة على الانترنت

المزيد من المعلومات

-

آلة صنع الرمل

رسالة على الانترنت

المزيد من المعلومات

-

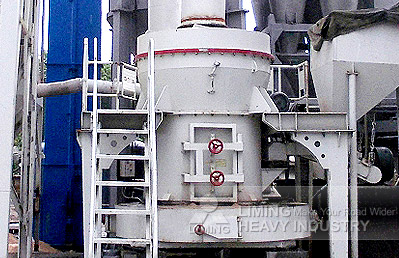

طاحونة عمودية-LM

رسالة على الانترنت

المزيد من المعلومات

-

طاحونة T130X الدقيقة

رسالة على الانترنت

المزيد من المعلومات

-

طاحونة رايموند

رسالة على الانترنت

المزيد من المعلومات

-

MTWطاحونة شبة المنح

رسالة على الانترنت

المزيد من المعلومات

-

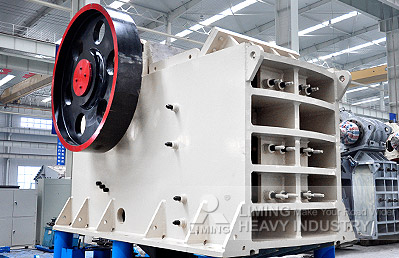

كسارة فكية

رسالة على الانترنت

المزيد من المعلومات

-

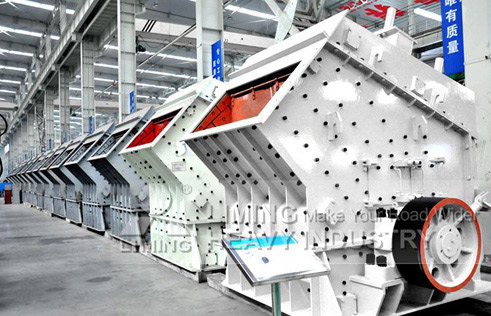

كسارة تصادمية

رسالة على الانترنت

المزيد من المعلومات

-

سلسلة CS كسارة مخرو

رسالة على الانترنت

المزيد من المعلومات

-

10-12 ·في سبتمبر 2018 ، اجتاز شهادة التجارة الإلكترونية في مقاطعة خنان.

في يونيو 2018 ، فازت الشركة بجائزة 'عقد الائتمان والائتمان' ومعيار صناعة آلات البناء الوطني 2017.

-

10-12 ·في مايو 2018 ، تم منحها مؤسسة الابتكار المستقلة لصناعة الآلات الثقيلة في الصين.

في مايو 2018 ، تم منحها مؤسسة الابتكار المستقلة لصناعة الآلات الثقيلة في الصين.

-

10-12في مايو 2018 ، تم منحها مؤسسة الابتكار المستقلة لصناعة الآلات الثقيلة في الصين.

في مايو 2018 ، تم منحها مؤسسة الابتكار المستقلة لصناعة الآلات الثقيلة في الصين.

-

10-12 ·أغسطس الشركة قدمت الكسارة الإمباكيت بالسلسلة CI5X .

أغسطس الشركة قدمت الكسارة الإمباكيت بالسلسلة CI5X .

-

10-12 ·مارس الشركة قدمت الة الرمل بالسلسلة VSI6X .

أغسطس الشركة قدمت الكسارة الإمباكيت بالسلسلة CI5X .

-

10-12 ·مارس الشركة قدمت الة الرمل بالسلسلة VSI6X .

مارس الشركة قدمت الة الرمل بالسلسلة VSI6X .

من نحن

لى مينغ للصناعات الثقيلة العلوم والتكنولوجيا في 30 السنوات الأخيرة من عملية التنمية، وتشكيل فريدة من نوعها، غنية المحتوى ثقافة الشركات. بناء ثقافة المؤسسة يمينغ للصناعات الثقيلة العلوم والتكنولوجيا التماسك والتضامن من نقطة التجميع، مصدر الطاقة من أجل التنمية المستدامة للمؤسسات.